Enqubweni yokukhiqiza amakhemikhali, ingcindezi ayithinti kuphela ubudlelwano bebhalansi kanye nezinga lokuphendula lenqubo yokukhiqiza, kodwa futhi ithinta imingcele ebalulekile yebhalansi yezinto zesistimu.Enqubweni yokukhiqiza yezimboni, ezinye zidinga ukucindezela okuphezulu kakhulu kunokucindezela komkhathi, njenge-polyethylene ephezulu yokucindezela.I-Polymerization yenziwa ngengcindezi ephezulu ye-150MPA, futhi enye idinga ukwenziwa ngomfutho ongemuhle ophansi kakhulu kunomfutho womoya.Okufana ne-vacuum distillation ezindaweni zokuhluza uwoyela.Ingcindezi ephezulu yesitimu yesitshalo samakhemikhali se-PTA ingu-8.0MPA, futhi umfutho wokuphakelwa komoyampilo ucishe ube ngu-9.0MPAG.Isilinganiso sokucindezela sikhulu kakhulu, umqhubi kufanele ahambisane ngokuqinile nemithetho yokusebenzisa amathuluzi okulinganisa ingcindezi ahlukahlukene, aqinise ukunakekelwa kwansuku zonke, nanoma yikuphi ubudedengu noma ukunganaki.Zonke zingase zibe nomonakalo omkhulu kanye nokulahlekelwa, ukwehluleka ukufeza izinhloso zekhwalithi ephezulu, isivuno esiphezulu, ukusetshenziswa okuphansi nokukhiqiza okuphephile.

Isigaba sokuqala umqondo oyisisekelo wokulinganisa ingcindezi

- Incazelo yokucindezeleka

Emkhiqizweni wezimboni, okuvame ukubizwa ngokuthi ingcindezi ibhekisela kumandla asebenza ngokufanayo nangokuma mpo endaweni yeyunithi, futhi usayizi wawo unqunywa indawo ephethe amandla kanye nobukhulu bamandla aqondile.Ivezwe ngezibalo kanje:

P=F/S lapho u-P eyingcindezi, u-F ungamandla aqondile kanye no-S indawo yamandla

- Iyunithi yokucindezela

Kwezobuchwepheshe bonjiniyela, izwe lami lamukela i-International System of Units (SI).Iyunithi yokubala yokucindezela i-Pa (Pa), 1Pa ingcindezi ekhiqizwa amandla angu-1 Newton (N) asebenza mpo nangokulinganayo endaweni eyimitha-skwele engu-1 (M2), evezwa njengokuthi N/m2 (Newton/ imitha yesikwele) , Ngaphezu kwe-Pa, iyunithi yokucindezela ingaba nama-kilopascals nama-megapascals.Ubudlelwano bokuguqulwa phakathi kwabo yilokhu: 1MPA=103KPA=106PA

Ngenxa yeminyaka eminingi yomkhuba, umfutho womoya wobunjiniyela usasetshenziswa kwezobunjiniyela.Ukuze kube lula ukuguqulwa okuhambisanayo ekusetshenzisweni, ubudlelwano bokuguqulwa phakathi kwamayunithi ambalwa okulinganisa ingcindezi avame ukusetshenziswa afakwe kuhlu ku-2-1.

| Iyunithi yokucindezela | Umkhathi wobunjiniyela Kg/cm2 | mmHg | mmH2O | i-atm | Pa | ibha | 1b/ku2 |

| Kgf/cm2 | 1 | 0.73×103 | 104 | 0.9678 | 0.99×105 | 0.99×105 | 14.22 |

| MmHg | 1.36×10-3 | 1 | 13.6 | 1.32×102 | 1.33×102 | 1.33×10-3 | 1.93×10-2 |

| MmH2o | 10-4 | 0.74×10-2 | 1 | 0.96×10-4 | 0.98×10 | 0.93×10-4 | 1.42×10-3 |

| I-Atm | 1.03 | 760 | 1.03×104 | 1 | 1.01×105 | 1.01 | 14.69 |

| Pa | 1.02×10-5 | 0.75×10-2 | 1.02×10-2 | 0.98×10-5 | 1 | 1×10-5 | 1.45×10-4 |

| Indawo yokuphuzela utshwala | 1.019 | 0.75 | 1.02×104 | 0.98 | 1×105 | 1 | 14.50 |

| Ib/ku2 | 0.70×10-2 | 51.72 | 0.70×103 | 0.68×10-2 | 0.68×104 | 0.68×10-2 | 1 |

- Izindlela zokuveza ukucindezeleka

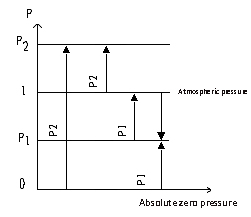

Kunezindlela ezintathu zokuveza ingcindezi: ingcindezi ephelele, ingcindezi yegeji, ingcindezi engemihle noma ivacuum.

Ingcindezi engaphansi kwe-absolute vacuum ibizwa ngokuthi i-absolute zero pressure, futhi ingcindezi evezwa ngesisekelo sengcindezi enguziro ibizwa ngokuthi i-absolute pressure.

Ingcindezi yegeyiji ingcindezi evezwa ngesisekelo somfutho womoya, ngakho-ke ikude ncamashi ne-atmosphere eyodwa (0.01Mp) kude nomfutho ophelele.

Okungukuthi: Ithebula elingu-P = P ngokuphelele-P elikhulu (2-2)

Umfutho ongemuhle uvame ukubizwa ngokuthi i-vacuum.

Kungabonakala kufomula (2-2) ukuthi ingcindezi engalungile ingcindezi yegeji lapho ukucindezela okuphelele kuphansi kunokucindezela komkhathi.

Ubudlelwano phakathi kwengcindezi ephelele, ingcindezi yegeji, ingcindezi engemihle noma i-vacuum iboniswa esithombeni esingezansi:

Iningi lamanani ezinkomba zengcindezi asetshenziswa embonini ingcindezi yegeji, okungukuthi, inani elikhombisayo legeji yokucindezela liwumehluko phakathi kokucindezela okuphelele nokucindezela komkhathi, ngakho ukucindezela okuphelele kuyisamba sokucindezela kwegeji nokucindezela komkhathi.

Isigaba 2 Ukuhlelwa Kwezinsimbi Zokukala Ingcindezi

Ibanga lengcindezi elizokalwa ekukhiqizweni kwamakhemikhali libanzi kakhulu, futhi ngalinye linomkhakha walo ngaphansi kwezimo zezinqubo ezihlukene.Lokhu kudinga ukusetshenziswa kwamathuluzi okulinganisa ingcindezi anezakhiwo ezahlukene kanye nezimiso zokusebenza ezihlukene ukuze kuhlangatshezwane nezidingo ezihlukahlukene zokukhiqiza.Izidingo ezahlukene.

Ngokwezimiso ezihlukene zokuguqulwa, amathuluzi okulinganisa ingcindezi angahlukaniswa cishe abe izigaba ezine: amageji omfutho wekholomu ewuketshezi;izikali ze-elastic pressure;izikali zokucindezela kagesi;izikali ze-piston pressure.

- Isilinganiso somfutho wekholomu yoketshezi

Umgomo wokusebenza wegeji yengcindezi yekholomu ye-liquid isekelwe kumgomo we-hydrostatics.Ithuluzi lokulinganisa ingcindezi elenziwe ngokwalesi simiso linesakhiwo esilula, esilungele ukusetshenziswa, sinokunemba kwesilinganiso esiphakeme kakhulu, sishibhile, futhi singakwazi ukukala izingcindezi ezincane, ngakho-ke sisetshenziswa kabanzi ekukhiqizeni.

Izikali zokucindezela kwekholomu yoketshezi zingahlukaniswa zibe izikali ze-U-tube pressure gauges, izikali zokucindezela kweshubhu eyodwa, kanye nezikali zokucindezela kweshubhu ethambekele ngokwezakhiwo zazo ezihlukene.

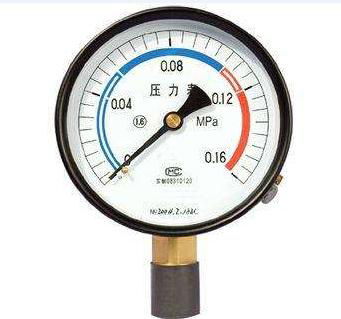

- I-Elastic pressure gauge

I-elastic pressure gauge isetshenziswa kakhulu ekukhiqizeni amakhemikhali ngoba inezinzuzo ezilandelayo, njengesakhiwo esilula.Iqinile futhi inokwethenjelwa.Inebanga lokulinganisa elibanzi, elisebenziseka kalula, lifundeka kalula, liphansi ngentengo, futhi linokunemba okwanele, futhi kulula ukwenza imiyalelo yokuthumela nokukude, ukurekhoda okuzenzakalelayo, njll.

I-elastic gauge ye-pressure gauge yenziwa ngokusebenzisa izakhi ezihlukahlukene zokunwebeka zomumo ohlukene ukuze kukhiqizwe ukuwohloka kwe-elastic ngaphansi kwengcindezi okufanele ilinganiswe.Ngaphakathi komkhawulo wokunwebeka, ukuphuma okukhiphayo kwento enwebekayo kusebuhlotsheni bomugqa nengcindezi okufanele ikalwe., Ngakho-ke isikali sayo siyafana, izingxenye ezinwebekayo zihlukile, ububanzi bokulinganisa ingcindezi buhlukile, njengezingxenye ze-diaphragm zikathayela kanye nezivunguvungu, ngokuvamile ezisetshenziswa ezikhathini zokulinganisa ingcindezi ephansi, ishubhu elilodwa lesiphethu sekhoyili (elifushanisiwe njengeshubhu lasentwasahlobo) kanye nabaningi. I-coil spring tube isetshenziselwa ukucindezela okuphezulu, okuphakathi noma ukulinganisa kwe-vacuum.Phakathi kwazo, ithubhu ye-spring-coil eyodwa inohlu olubanzi lokulinganisa ingcindezi, ngakho-ke isetshenziswa kakhulu ekukhiqizeni amakhemikhali.

- Ama-Pressure Transmitters

Njengamanje, ama-transmitter kagesi kanye ne-pneumatic pressure asetshenziswa kakhulu ezitshalweni zamakhemikhali.Ziyithuluzi eliqhubeka nokukala ingcindezi elinganisiwe futhi liyiguqule libe amasignali ajwayelekile (umfutho womoya kanye nowamanje).Zingadluliselwa ngokuhamba amabanga amade, futhi ingcindezi ingaboniswa, irekhodwe noma ilungiswe ekamelweni lokulawula eliphakathi.Zingahlukaniswa zibe ingcindezi ephansi, ingcindezi ephakathi, ingcindezi ephezulu kanye nengcindezi ephelele ngokuya ngezigaba ezihlukene zokulinganisa.

Isigaba sesi-3 Isingeniso Sezinsimbi Zokucindezela Ezitshalweni Zamakhemikhali

Ezitshalweni zamakhemikhali, i-Bourdon tube gauge ye-pressure gauge ivame ukusetshenziselwa izikali zokucindezela.Kodwa-ke, i-diaphragm, i-diaphragm enothayela kanye nezikali ze-spiral pressure nazo zisetshenziswa ngokuvumelana nezidingo zomsebenzi kanye nezidingo zezinto ezibonakalayo.

Ububanzi obujwayelekile begeji yengcindezi esendaweni ngu-100mm, futhi impahla iyinsimbi engagqwali.Ifaneleka kuzo zonke izimo zezulu.Igeji yengcindezi enejoyinti lekhoni elihle elingu-1/2HNPT, ingilazi yokuphepha kanye nolwelwesi lwe-vent, inkomba esendaweni kanye nokulawula kunomoya.Ukunemba kwayo kungu-±0.5% wesilinganiso esigcwele.

Isidlulisi somfutho kagesi sisetshenziselwa ukudlulisa isignali ukude.Ibonakala ngokunemba okuphezulu, ukusebenza kahle, nokuthembeka okuphezulu.Ukunemba kwayo kungu-±0.25% wesilinganiso esigcwele.

I-alamu noma isistimu yokukhiya isebenzisa inkinobho yokucindezela.

Isigaba 4 Ukufakwa, Ukusetshenziswa kanye Nokugcinwa Kwezilinganiso Zokucindezela

Ukunemba kokulinganisa ingcindezi akuhlobene nje nokunemba kwegeji yokucindezela ngokwayo, kodwa futhi ukuthi ifakwe ngokunengqondo, kungakhathaliseki ukuthi ilungile noma cha, nokuthi isetshenziswa futhi igcinwe kanjani.

- Ukufakwa kwegeji yokucindezela

Uma ufaka i-gauge yokucindezela, kufanele kuqashelwe ukuthi indlela yokucindezela ekhethiwe kanye nendawo ifanelekile, enomthelela oqondile empilweni yayo yesevisi, ukunemba kokulinganisa kanye nekhwalithi yokulawula.

Izidingo zamaphuzu okulinganisa ingcindezi, ngaphezu kokukhetha kahle indawo ethile yokulinganisa ingcindezi emshinini wokukhiqiza, ngesikhathi sokufakwa, indawo yokugcina yangaphakathi yepayipi lokucindezela elifakwe kumshini wokukhiqiza kufanele igcinwe ishaywa ngodonga lwangaphakathi lwephoyinti lokuxhuma. wempahla yokukhiqiza.Akufanele kube nama-protrusions noma ama-burrs ukuze kuqinisekiswe ukuthi ukucindezela okumile kutholakala ngendlela efanele.

Indawo yokufaka kulula ukuyibona, futhi ulwele ukugwema ithonya lokudlidliza nokushisa okuphezulu.

Lapho ukala umfutho we-steam, ipayipi ye-condensate kufanele ifakwe ukuvimbela ukuthintana okuqondile phakathi kwe-steam ephezulu yokushisa kanye nezingxenye, futhi ipayipi kufanele ifakwe insulated ngesikhathi esifanayo.Kumithombo yezindaba ebolayo, amathangi okuhlukanisa agcwele imidiya engathathi hlangothi kufanele afakwe.Ngamafuphi, ngokusho kwezakhiwo ezahlukene ze-medium elinganisiwe (ukushisa okuphezulu, izinga lokushisa eliphansi, ukugqwala, ukungcola, i-crystallization, imvula, i-viscosity, njll.), thatha izinyathelo ezihambisanayo zokulwa nokugqwala, ukulwa nokuqhwa, izinyathelo zokuvimba.I-valve yokuvala kufanele futhi ifakwe phakathi kwechweba elithatha ukucindezela kanye ne-gauge ye-pressure gauge, ukuze lapho i-gauge ye-pressure idluliswa, i-valve yokuvala kufanele ifakwe eduze kwechweba elithatha ukucindezela.

Endabeni yokuqinisekiswa kwendawo kanye nokushaywa njalo kweshubhu lomfutho, i-valve yokuvala ingaba yi-switch yezindlela ezintathu.

I-catheter eqondisayo yokucindezela akufanele ibe yinde kakhulu ukunciphisa ukuvilapha kwenkomba yengcindezi.

- Ukusetshenziswa nokugcinwa kwe-pressure gauge

Ekukhiqizeni amakhemikhali, ama-gauge okucindezela avame ukuthinteka phakathi kokulinganiswa okufana nokugqwala, ukuqiniswa, i-crystallization, i-viscosity, uthuli, ukucindezela okuphezulu, izinga lokushisa eliphezulu, nokuguquguquka okubukhali, okuvame ukubangela ukwehluleka okuhlukahlukene kwegeji.Ukuze kuqinisekiswe ukusebenza okuvamile kwethuluzi, ukunciphisa ukwenzeka kokwehluleka, nokwandisa impilo yesevisi, kuyadingeka ukwenza umsebenzi omuhle wokuhlola ukugcinwa nokugcinwa kokunakekelwa okujwayelekile ngaphambi kokuqala kokukhiqiza.

1. Ukugcinwa nokuhlolwa ngaphambi kokuqala kokukhiqiza:

Ngaphambi kokuqala kokukhiqiza, umsebenzi wokuhlola ingcindezi ngokuvamile uyenziwa kumishini yenqubo, amapayipi, njll. Ingcindezi yokuhlola ivamise ukuba izikhathi ezi-1.5 zokucindezela kokusebenza.I-valve exhunywe kuthuluzi kufanele ivalwe ngesikhathi sokuhlolwa kwengcindezi yenqubo.Vula i-valve kudivayisi ethatha ukucindezela bese uhlola ukuthi akukho yini ukuvuza emalungeni nasekushiseleni.Uma kukhona ukuvuza kutholakala, kufanele kuqedwe ngesikhathi.

Ngemva kokuhlolwa kwengcindezi sekuqediwe.Ngaphambi kokulungiselela ukuqala ukukhiqiza, hlola ukuthi ukucaciswa kanye nemodeli yegeji yokucindezela efakiwe kuyahambisana yini nokucindezela kwendawo elinganisiwe edingwa inqubo;ukuthi igeji elinganisiwe inaso yini isitifiketi, futhi uma kukhona amaphutha, kufanele alungiswe ngesikhathi.Igeji ye-liquid pressure gauge idinga ukugcwaliswa ngoketshezi olusebenzayo, futhi iphuzu elinguziro kufanele lilungiswe.Igeji yokucindezela efakwe idivayisi yokuhlukanisa idinga ukungeza uketshezi oluhlukanisayo.

2. Ukugcinwa nokuhlolwa kwegeji yomfutho lapho ushayela:

Ngesikhathi sokuqala kokukhiqiza, ukulinganisa ukucindezela kwe-pulsating medium, ukuze kugwenywe ukulimala kwesilinganiso sokucindezela ngenxa yomthelela osheshayo nokucindezela ngokweqile, i-valve kufanele ivule kancane futhi izimo zokusebenza kufanele zibonwe.

Ukuze uthole ama-gauge okucindezela okulinganisa umusi noma amanzi ashisayo, i-condenser kufanele igcwaliswe ngamanzi abandayo ngaphambi kokuvula i-valve ku-gauge yokucindezela.Uma kutholakala ukuvuza kwensimbi noma ipayipi, i-valve emshinini othatha ukucindezela kufanele inqanyulwe ngesikhathi, bese ubhekana nayo.

3. Ukugcinwa kwansuku zonke kwegeji yokucindezela:

Ithuluzi elisebenzayo kufanele lihlolwe njalo nsuku zonke ukuze kugcinwe imitha ihlanzekile futhi kuhlolwe ubuqotho bemitha.Uma inkinga itholakele, yisuse ngesikhathi.

Isikhathi sokuthumela: Dec-15-2021