I-Turbine Flow Meters: Ukunemba kanye Nokwethenjelwa Kwezimboni Zanamuhla

Njengoba umkhakha wamandla emhlabeni wonke ubhekela kumafutha ahlanzekile kanye nokuziphendulela okuqinile kwezinsiza,turbine flow metreshlala uyisisekelo sokulinganisa ukugeleza okunembile kuzo zonke izimboni ezihlukahlukene. Le mishini iletha ukunemba okukhethekile, ukuthobela izindinganiso zamazwe ngamazwe, nokusebenza ngendlela eyongayo, okuyenza ibaluleke kakhulu ekusebenziseni igesi yemvelo ewuketshezi (I-LNG) ukudluliswa kwesitokisi ku-sustainable aviation fuel (SAF) nokucutshungulwa kwamakhemikhali. Lo mhlahlandlela obanzi uhlola ukuthi amamitha okugeleza kwama-turbine asebenza kanjani, izinzuzo zawo, izinhlelo zokusebenza ezibalulekile, indlela yokukhetha, izinqubo ezingcono kakhulu zokunakekela, kanye nokuzivumelanisa kwazo nezidingo zemboni esafufusa.

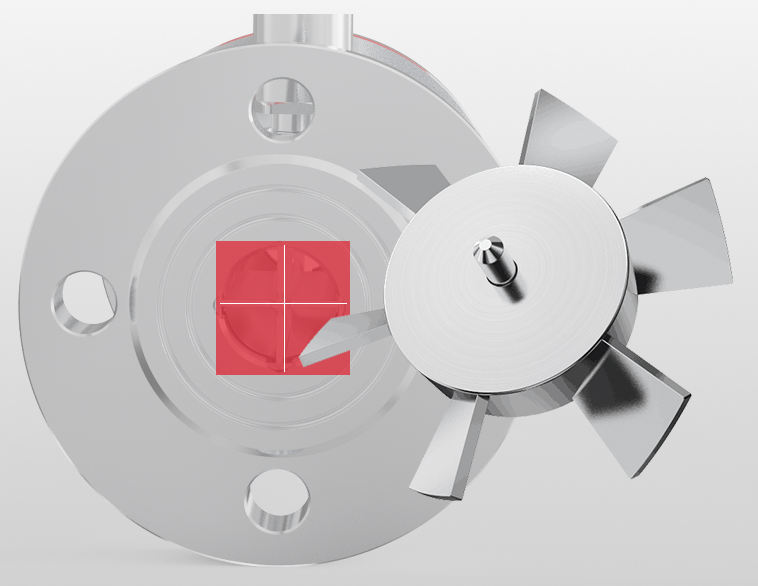

Isebenza kanjani i-Turbine Flow Meters

Amamitha okugeleza ka-turbine akalaizinga lokugelezazoketshezi noma amagesi ngokusebenzisa isivinini sokujikeleza kwesondo le-turbine yangaphakathi. Njengoba uketshezi ludlula kumitha, lubangela ukuba i-turbine ijikeleze ngenani elilinganayo nesilinganiso sokugeleza kwevolumu. Izinzwa zibona ukuzungezisa, ngokuvamile ngokucosha kazibuthe noma ukubona, futhi zikuguqulele kusignali ye-elekthronikhi ukuze kukale ukugeleza okunembile.

Uma ibhangqwe neziguquli zesignali ze-elekthronikhi ezithuthukisiwe, amamitha okugeleza kwe-turbine ahlinzeka ngokufunda okusheshayo, okuphindaphindayo, nokunembile, ngokuvamile azuza ukunemba okungu-±0.5% kuya ku-±1% phakathi kwebanga lawo lokusebenza elicacisiwe. Lokhu kubenza balungele uketshezi oluhlanzekile, olune-viscosity ephansi, njengamanzi, izinto zokubasa, izincibilikisi, namagesi, asetshenziswa ezimbonini lapho ukunemba kubaluleke khona.

Izinzuzo ezibalulekile ze-Turbine Flow Meters

Iturbine metreszinikeza izinzuzo ezimbalwa ezizenza kube ukukhetha okuthandwayo ezimbonini ezidinga ukulinganisa okuthembekile kokugeleza. Ngezansi izinzuzo zabo eziyinhloko:

Ukunemba Okukhethekile Nokuphindaphindwa

Amamitha okugeleza kwe-turbine aletha ukunemba okuphezulu, nokuphindaphinda okuqinile njengo-±0.5% kanye nokukhukhuleka okuncane kwesikhathi eside. Lokhu kubenza bafanelekele izinhlelo zokusebenza ezibucayi ezifana nokudluliselwa kwesitokisi, lapho ukulinganisa okunembile kuqinisekisa ukuthengiselana kwezezimali okufanelekile. Athobela izindinganiso eziqinile, njenge-API MPMS Chapter 5 (Petroleum Measurement Standards) kanye ne-OIML R117 (Izinhlelo zokukala Dynamic zoketshezi), ezifaka izicelo zokudluliselwa kwesitokisi ezimbonini zikawoyela, igesi, namakhemikhali.

Isikhathi Sokuphendula Esisheshayo

Ngezikhathi zokuphendula ezingaphansi kwama-millisecond angu-100, amamitha okugeleza kwe-turbine anika amandla ukuqapha nokulawula kwesikhathi sangempela kumasistimu aguquguqukayo. Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza ezifana nezingalo zokulayisha uphethiloli, ukucutshungulwa kwenqwaba, nokudosa okuzenzakalelayo, lapho ukulungiswa okusheshayo koshintsho lokugeleza kubalulekile.

I-Compact Design kanye Nezindleko Ezinhle

Amamitha okugeleza ka-turbine afaka idizayini elula yemishini, ngokuvamile eyakhiwe ngezinto ezihlala isikhathi eside njengensimbi engagqwali noma i-Hastelloy. Lokhu kubalula kuhumushela ezindlekweni zokufaka eziphansi kanye nokulungiswa okuncishisiwe uma kuqhathaniswa nobuchwepheshe obuyinkimbinkimbi, obufana ne-Coriolis noma ama-flow metres e-ultrasonic. Usayizi wabo ohlangene futhi ubenza kube lula ukuhlanganisa nezinhlelo ezikhona.

Ibanga Lokusebenza Olubanzi

Amamitha okugeleza kwama-turbine asebenza ngokwethembeka kulo lonke uhla olubanzi lwezingcindezi namazinga okushisa, kusukela ezimeni ezikhalayo ezifika ku--200°C kuya ezindaweni ezinezinga lokushisa eliphezulu elifika ku-+400°C. Amamodeli ayisipesheli angakwazi ukubhekana nezingcindezi ezifika ku-10,000 psi (690 bar), azenze zifanelekele izinhlelo zokusebenza ezinzima ezifana nokudlulisa i-LNG noma ukucubungula kwe-hydrocarbon ephezulu.

Izicelo Zemboni Ye-Turbine Flow Meters

Izilinganiso zokugeleza kwe-turbine ziyahlukahluka futhi zisetshenziswa kabanzi kuzo zonke izimboni ezifuna ukunemba nokuhambisana. Ngezansi ezinye zezicelo zabo ezibalulekile:

I-LNG kanye ne-Hydrocarbon Custody Transfer

Njengoba izimakethe zamandla omhlaba zithuthuka, njengoba i-Europe ihlukanisa imithombo yayo yamandla kanye ne-Asia inyusa ukuthengwa kwe-LNG, amamitha okugeleza ohlobo lwe-turbine adlala indima ebalulekile ekusebenzeni kokudluliselwa kwesitokisi. Lawa mamitha aqinisekisa ukukalwa okunembile kwegesi yemvelo ewuketshezi (LNG), igesi yemvelo ecindezelwe (CNG), nama-hydrocarbon acwengisisiwe, asekela ukuhweba okulungile kokuthengiselana kwamandla anenani eliphezulu.

Ukuthobela kwabo izindinganiso zamazwe ngamazwe, okuhlanganisa i-API, i-OIML, ne-ISO, kuqinisekisa ukwethembeka kumadili ezigidigidi. Isibonelo, ekudlulisweni kokugcinwa kwe-LNG, amamitha okugeleza kwe-turbine ahlinzeka ngokunemba okudingekayo ukuze kulandelwe yonke i-cubic meter yomkhiqizo, ukwehlisa izingxabano zezimali kanye nokuqinisekisa ukuthobela imithetho.

I-Aviation Fueling kanye ne-Sustainable Aviation Fuel (SAF)

Imboni yezokundiza ingaphansi kwengcindezi yokuthola ukukhishwa kwe-net-zero, ukushayela isidingo sikaphethiloli wendiza eqhubekayo (SAF) kanye namafutha ejethi endabuko. Amamitha okugeleza kwe-turbine abalulekile ekukaleni uphethiloli okunembile ngesikhathi sokusebenza kwendiza, ukuqinisekisa ukuphepha nokusebenza kahle.

Amamitha ophephela emhlane aklanyelwe ukuphatha i-viscosity eguquguqukayo yenhlanganisela ye-SAF, ehlanganisa amasu okulinganisa athuthukisiwe nama-algorithms okunxeshezelwa kwezinga lokushisa. Lokhu kubenza bakwazi ukugcina ukunemba kuqinile njengokungu-±0.35% ngesikhathi sokuhlanganisa, kuqinisekiswe ukusebenza okufanayo kungakhathaliseki ukuthi kukala izibaseli ezisekelwe kuphalafini zendabuko noma i-SAF eco-friendly.

Ukucubungula Amakhemikhali Nemithi

Ezimbonini zamakhemikhali nezemithi, amamitha okugeleza ka-turbine asekela uchungechunge lwezinqubo ezibalulekile, okuhlanganisa:

-

Precision Batch Dosing: Ngokuphindaphinda okuphansi okungafika ku-±0.25%, ama-turbine metres aqinisekisa ukulethwa okunembile kwamakhemikhali nama-reactants ezinqubweni zeqoqo, ukunciphisa ukungcola nokuqinisekisa ikhwalithi yomkhiqizo.

-

Ukulawulwa kwe-Solvent kanye ne-Reactant: Ekukhiqizweni kwemithi, ukukalwa kokugeleza okunembile kubalulekile ekulawuleni izinyibilikisi nama-reactants, ukuqinisekisa ukwakheka okungaguquki nokuhambisana nezindinganiso zokulawula.

-

Ukupholisa kanye Nezinhlelo Zokujikeleza: Amamitha omshini wokuthungatha aqapha ukugeleza kumasistimu okupholisa ukuze abhekane ne-exothermic, esiza ukugcina izimo zokusebenza eziphephile.

Ikhono lazo lokuphatha uketshezi oluhlanzekile, olune-viscosity ephansi lizenza isixazululo salezi zinhlelo zokusebenza, lapho nokuchezuka okuncane kungase kuthinte ikhwalithi yomkhiqizo noma inqubo yokuphepha.

Imihlahlandlela yokukhetha yama-Turbine Flow Meters

Ukukhetha imitha yokugeleza ye-turbine efanele kudinga ukucatshangelwa ngokucophelela kwezinto ezimbalwa ukuze kuqinisekiswe ukusebenza kahle. Ngezansi izincomo ezibalulekile:

| Isici | Isincomo |

|---|---|

| I-Viscosity ye-Fluid | Ifaneleka kakhulu uketshezi olune-viscosity engaphansi kuka-50 cSt (0–20 cSt ilungile). Ukuze uthole uketshezi olune-viscosity ephezulu, cabangela igiya eliqanda noma amamitha okugeleza kwe-Coriolis. |

| Ukuhlanzeka Kwamanzi | Sebenzisa isihlungi sangaphambili esingu-100-micron ukuze uvikele ama-turbine bearings kuma-particle. Gwema imidiya e-fibrous noma elimazayo engalimaza izingxenye zangaphakathi. |

| Ukulinganisa | Khetha ukulinganisa okulandelekayo kwe-NIST kwezinhlelo zokusebenza zokudlulisa ukugcinwa. Ukulinganisa inkambu ngamasistimu okuqinisekisa kuyanconywa ukuze kube nokunemba okuqhubekayo. |

| Ukufakwa | Qinisekisa ubuncane obungamadayimitha amapayipi ayi-10 (10D) wepayipi eliqondile elikhuphuka nomfula kanye namadayamitha amapayipi angu-5 (5D) ezansi nomfula. Sebenzisa ama-flow conditioners ekusetheni okubambezeleke esikhaleni ukuze unciphise isiyaluyalu. |

Ukukhetha okufanele kuqinisekisa ukuthi imitha isebenza ngaphakathi kwebanga elifanele, iletha ukusebenza okuthembekile nokuphila isikhathi eside.

Ukugcinwa Kwezindlela Ezingcono Kakhulu zamamitha okugeleza kwe-Turbine

Ukwandisa isikhathi sokuphila kanye nokunemba kwamamitha okugeleza kwe-turbine, ukunakekelwa okuvamile kubalulekile. Ngezansi kukhona amasu afakazelwe okugcina amamitha akho esesimweni esiphezulu:

Faka Izihlungi Ezingaphakathi Komugqa

Ukusebenzisa izihlungi zensimbi engagqwali eziyi-100-micron kuvimbela izinhlayiya ukuthi zingangeni kumitha kanye nokulimaza ama-turbine bearings. Ekufakweni koketshezi oluhlanzekile, lokhu kungelula impilo yesevisi yemitha iye eminyakeni emihlanu noma ngaphezulu. Hlola izihlungi njalo ngekota ukuze uvimbele ukunqwabelana okungase kukhawulele ukugeleza futhi kuthinte ukunemba kokulinganisa.

Vimbela Cavitation kanye Pressure Spikes

I-Cavitation, ebangelwa ukwakheka kwebhamuza le-vapor, ingalimaza ama-turbine blades futhi inciphise ukunemba. Gcina i-overpressure encane ye-10% (noma okungenani ibha ye-1) ukuvimbela i-cavitation. Kumasistimu anama-valve avala ngokushesha, faka izinto ezinciphisa ukucindezela ukuze unciphise ukukhuphuka komfutho. Kuzinhlelo zokusebenza ezibandakanya amaphampu aphindaphindayo, cabangela izinto zokudambisa i-pulsation ukuze uhlelembe ukuhlukahluka kokugeleza.

Hlela Ukulinganisa Okuvamile

Ngezicelo zokudluliselwa kwesitokisi, linganisa kabusha amamitha okugeleza kwe-turbine njalo ngonyaka usebenzisa amamitha ayinhloko noma ama-prover ukuze ugcine ukuthobelana nezindinganiso. Ezinhlelweni ezijwayelekile zokulawula inqubo, ukulinganisa njalo eminyakeni emi-2-3 kwanele. Hlala ulinganisa kabusha ngemva kokulungiswa okubalulekile noma uma ubona ukunemba kukhukhuleka ngaphezu kokubekezelelwa okwamukelekayo (isb, ±1%).

Ukuzivumelanisa Nezidingo Zemboni Yesimanje

Amamitha okugeleza kwama-turbine athuthukile ukuze ahlangabezane nezinselelo zezimboni zesimanje, afaka izinto ezithuthukisiwe nobuchwepheshe bokuthuthukisa ukusebenza. Izindlela ezintsha eziqanjiwe zihlanganisa:

-

Izinto ze-Cryogenic: Amamitha akhiwe ngensimbi engagqwali 316L noma i-Monel aklanyelwe izinhlelo zokusebenza ze-LNG emazingeni okushisa aphansi njenge -162 ° C, okuqinisekisa ukuqina ezimweni ezimbi kakhulu.

-

Ukwakhiwa Okumelana Nokugqwala: I-Hastelloy C-276 isetshenziselwa amamitha aphatha ama-biofuels adlayo, amakhemikhali, noma izincibilikisi, inweba impilo yesevisi ezindaweni ezinolaka.

-

Ukuhlanganiswa Kwedijithali: Amamitha ophephela emhlane asekela izimiso zokuxhumana zedijithali ezifana ne-Modbus, i-HART, ne-Foundation Fieldbus, evumela ukuhlanganiswa okungenazihibe nezinhlelo ze-Industrial 4.0 zokuqapha idatha ngesikhathi sangempela kanye nezibalo.

Lezi ntuthuko zenza amamitha okugeleza kwama-turbine abe yisixazululo sobufakazi besikhathi esizayo sezimboni ezizulazula ekushintsheni kumafutha ahlanzekile kanye nezinqubo zokukhiqiza ezihlakaniphile.

Isiphetho

Amamitha okugeleza kwama-turbine ahlanganisa ukunemba, ukwethembeka, kanye nokusebenza kahle kwezindleko, okuwenza abe yinketho eguquguqukayo ezimbonini ezisukela kumandla kuya kwezokundiza kuya ekucutshungulweni kwamakhemikhali. Ikhono labo lokuletha izilinganiso ezinembile ezimweni ezinzima, ukuthobela izindinganiso zomhlaba wonke, futhi ukuhlanganisa nezinhlelo zesimanje zedijithali kuqinisekisa ukuthi bahlala beyithuluzi elithenjwayo lochwepheshe emhlabeni wonke.

Kungakhathaliseki ukuthi ulawula ukudluliswa kwelungelo lokutholwa kwe-LNG, uphethiloli wendiza ngophethiloli wendiza osimeme, noma ulawula umthamo wamakhemikhali, amamitha okugeleza kwe-turbine ahlinzeka ngokusebenza nokwethembeka okudingekayo ukuze kuhlangatshezwane nezinselele zanamuhla. Ngokulandela ukukhetha okufanele, ukufakwa, kanye nezinqubo zokunakekela, ungaqinisekisa ukuthi lawa mamitha aletha imiphumela engaguquki eminyakeni ezayo.

Isikhathi sokuthumela: Sep-18-2025